Our materials

Since 1975, our R&D department has been working with material manufacturers to develop formulas that meet our quality requirements and the needs of professionals. Podiatech has been listening to practitioners for over 40 years, and has developed a comprehensive and ever-evolving range of materials, from top covers and technical materials to resin and foam bases.

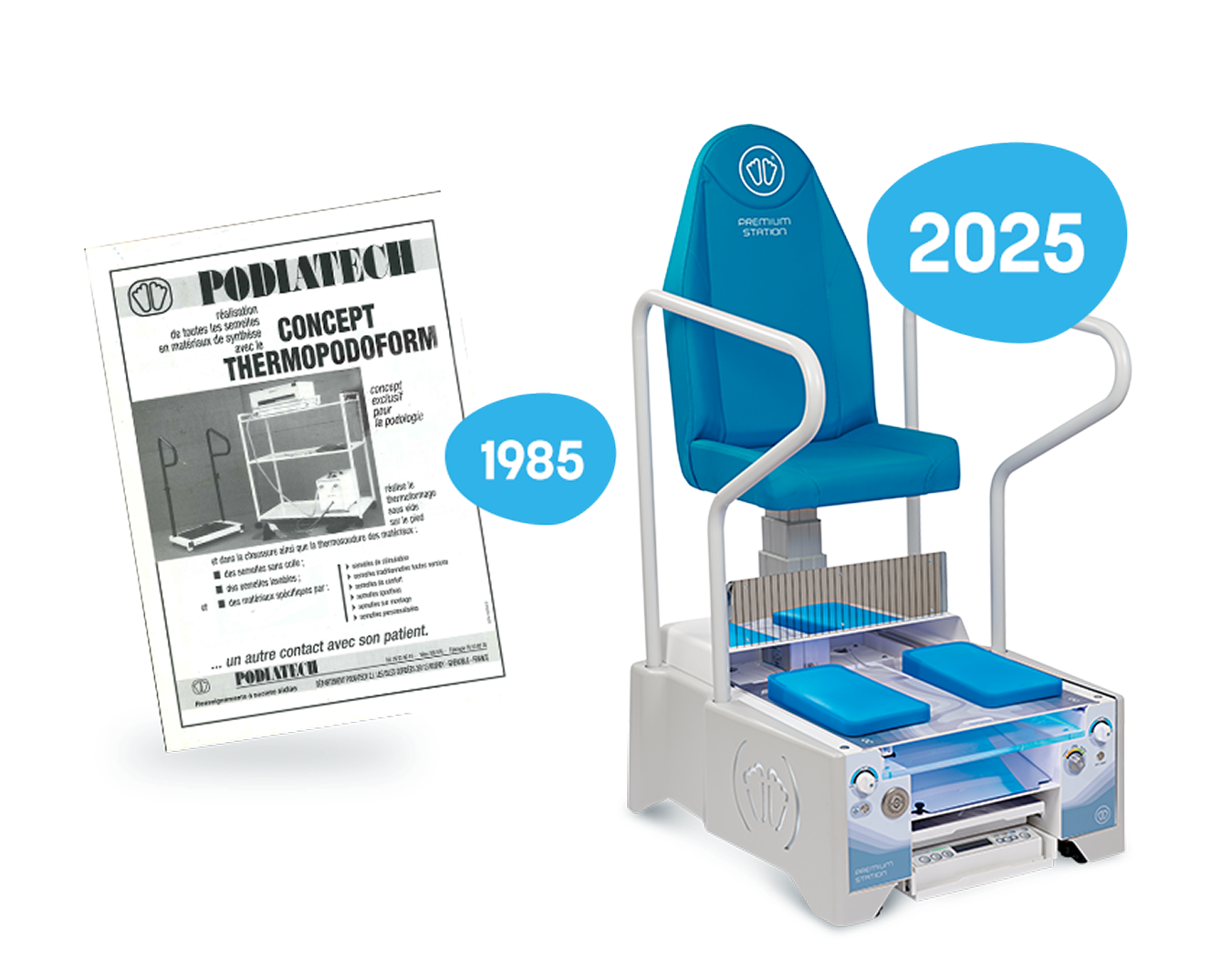

Thermoforming

We wanted to offer comprehensive solutions, above and beyond insoles. The logical next step was to move into machine design. Podiatech created the very first concept allowing for custom insoles to be thermoformed directly under the patient's foot: the Thermopodoform (the precursor of the Premium Station™). It has revolutionised the way insoles are made.

Since then, our R&D department has continued to innovate in the field of thermoforming by creating increasingly efficient and intuitive machines such as the Podolab® Master and the Premium Station™, which optimise practitioners' work.

Thanks to these new machines, practitioners can approach clinical examinations differently, allowing them to spend more time with their patients. At the end of their appointment, patients receive a pair of orthotic insoles, which they can try out to give their practitioner instant feedback.

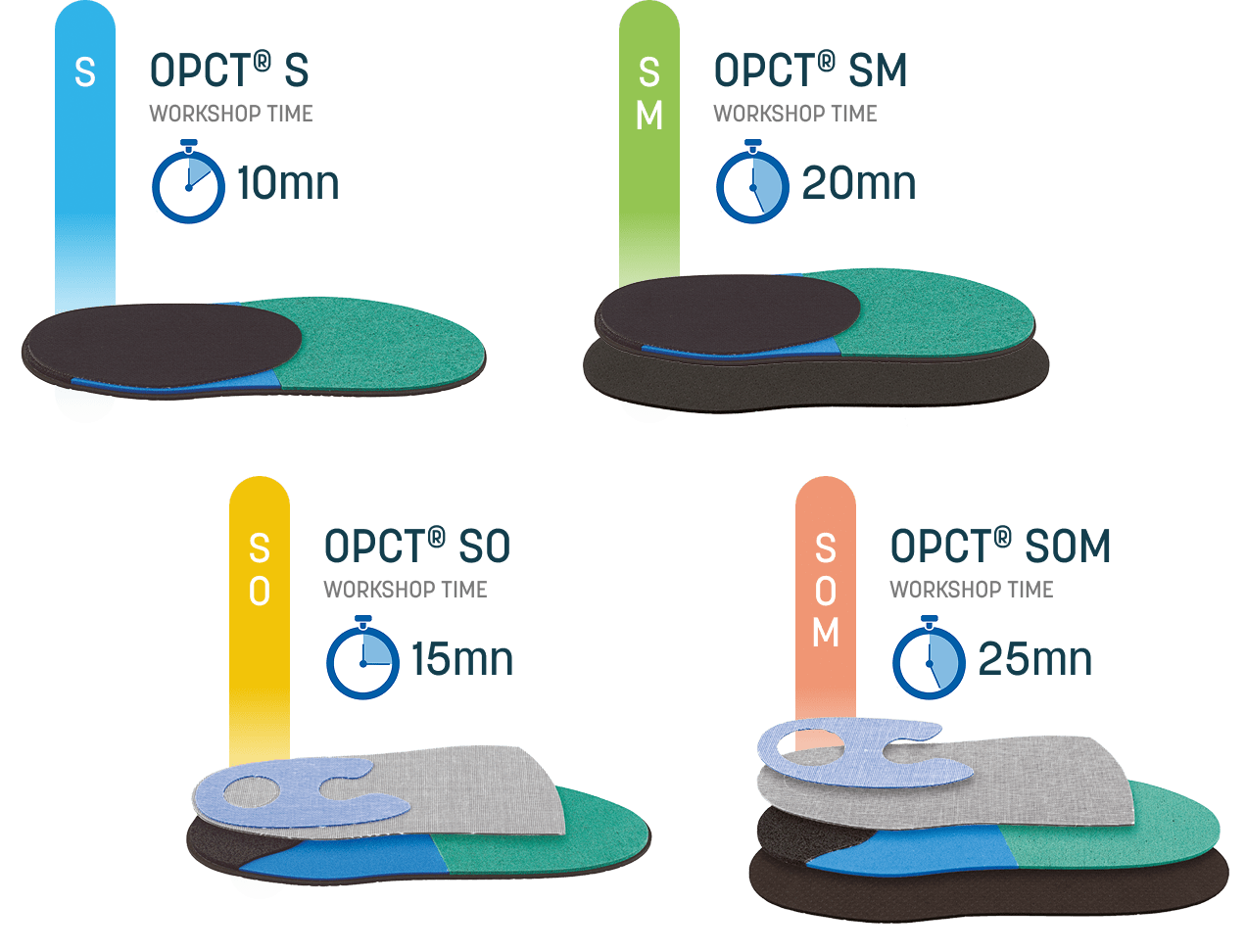

The OPCT®

In order to facilitate the work of practitioners, we sought to design an alternative to sheet materials, minimising both the storage space and handling and assembly time. Drawing on its in-depth knowledge of materials, our R&D department has developed a pre-designed solution for assembling materials in true synergy. In 1997, the OPCT® – the Thermoformable Composite Orthotic Insole – was born!

To adapt to each professional's approach, Podiatech offers four flat versions (S, SM, SO and SOM) and two curved versions (S+ and SM+), making the OPCT® a fully customisable module. Depending on the version selected, the base, middle layer and top cover may be glued or separate. Thanks to this concept, practitioners can add various elements depending on the selected version. OPCT® technology saves time when designing orthotic insoles, allowing practitioners to devote more time to patients during the analysis part of the consultation.

We have developed a constantly evolving range of OPCT® products to meet the needs of patients and follow trends in terms of fashion, sports and activities, ensuring comfort and pathological relief, and adapting to different styles of footwear.

Find out moreThe OPCT® FACTORY

We developed the OPCT® Factory service to protect practitioner's health and simplify their day-to-day work. This solution allows practitioners to outsource the insole creation process, saving time in the workshop, optimising stock management and ensuring reproducibility at the click of a button. Find out more

Find out more