Explore our range of services designed to optimise your time and enhance your working comfort.

Cutting based on our shapes

All the materials offered by PODIATECH in sheets can be supplied in the form of pre-cut modules based on our patterns.

Cutting based on your shapes

Whatever your specific shape requirements, we will create them for you. Contact us to discuss minimum order volumes and the procedure (technical file).

Choose your foam or resin bases, your top layers or elements and reinforcements. We work with you to define the shapes and materials that best suit your working technique and requirements.

Design your own personalised orthotic from start to finish! Choose the pattern shape and determine the material for each component, from top layers to reinforcements, not forgetting the intermediate bases and technical materials!

Let us take care of some of your every day needs!

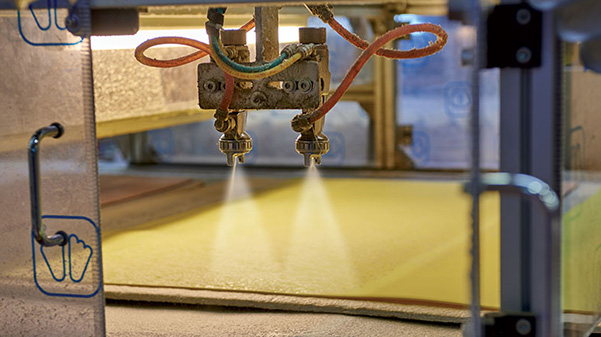

To avoid handling adhesives and solvents, which can be harmful in the long term, we can use our dedicated production tools to apply them for you. Whether it's pre-coating a single sheet or bonding multiple materials together, our methods department will advise you on the best solution (adhesive or glue) depending on the materials chosen.

Some materials require glue to hold them in place over time. Our tools and teams will pre-glue these for you, to save you workshop time and care for your health.

To protect the environment and the health of all involved, we offer double-sided adhesive for your sheets. Save workshop time too each day.

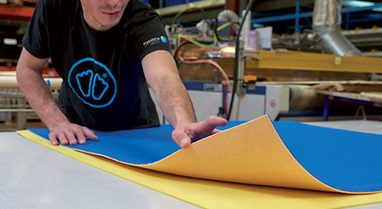

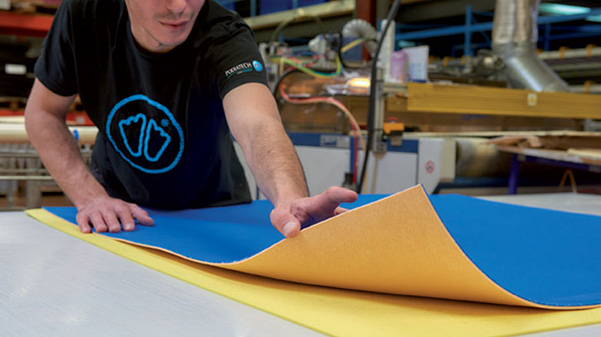

Glue lamination is carried out using special tools to ensure even, regular application and perfect bonding between your chosen materials.

Adhesive lamination is also offered wherever possible when materials permit. We guarantee friction and abrasion resistance by choosing a top-of-the-range, high-performance adhesive.

We can provide our OPCT or your own custom-made bespoke models in neutral forms.

A ready-to-use working base that can be modified if required, and that facilitates certain moulding methods. Delivery can be with the top layer either glued or separate (subject to technical feasibility), with no minimum quantity requirement, available in sizes 35 to 45. Please contact us for delivery conditions and times.

OPCT S+

The entire OPCT module is assembled and thermoformed (base/intermediate/top layer)

OPCT SM+

The top layer is separated from the assembly (base + intermediate), allowing for the inclusion of relief and comfort elements closest to the foot.