The OPCT® Factory, a simple principle

The podiatrist performs a scan of the patient's footprint and then sends it to the Podiatech production team using the Podiatech app.

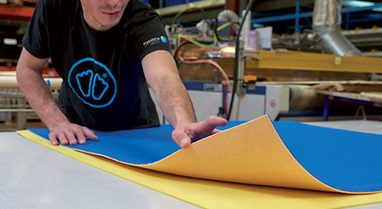

Upon receiving the scan and adhering to the specifications validated by the podiatrist, Podiatech professionals proceed with the machining and thermoforming of the OPCT®.

There are over 60 models of OPCT®, all manufactured in France and customisable to various degrees, catering to all budgets and patients.

How the OPCT® Factory works

No training is required to use the OPCT® Factory! Simple explanations relayed by tutorials available on the Podiatech YouTube channel make it easy to get started with the application. Also note that when you start using the OPCT® Factory, Podiatech provides you with 5 pairs of OPCT® and 10 impression boxes so you can test the tool. Upon your registration to the OPCT® Factory, Podiatech provides you with an iPad and a 3D scanner (the "Structure Sensor") that attaches to the rear face of the iPad, transforming it into a portable scanner for impression taking of your patients. You will then need several applications:

- The "Calibrator" application: Depending on the room in which the impression is taken, it can be used to calibrate the scan, which is very sensitive to light.

- The Podiatech app: An interface between the impression and the order, where you will record the data of each patient (name, shoe size, clinical examinations, scan of their impressions, type of insole chosen, corrections made, etc.).

- The Voxel Scan application: You will use this to take the patient's impression and to load it into the Podiatech app.

The advantages of the OPCT® Factory

The OPCT® Factory is:

- Compatible with most existing 3D scans: simple STL files are required, and importing into the application is extremely easy;

- Compatible with all impression-taking techniques: vacuum impression pads (ESVS), scanning the patient's foot, or using one of their old insoles;

- Adapted to the needs of the podiatrist, who can choose their workshop time with three levels of personalisation: PRO, ADVANCE, and ELITE, the latter two allowing for correction of the foot orthosis or addition of elements;

- Can be used connected to the Internet or offline (at home or at the hospital, the podiatrist can scan impressions of their patients and then connect to their practice to finalise and transmit their orders);

- Adaptable: the insole can be modified upon receipt if necessary after fitting;

- Safe and efficient: the OPCT® are manufactured on the Podiatech premises in Isère and are subjected to rigorous quality control.

Why entrust the manufacture of your insoles to the OPCT® Factory?

- Your OPCT® meet your quality requirements and those of your patients.

- They can be reproduced identically without the need for a scan of the impressions.

- You reduce your investment in equipment.

- You save space in your business premises.

- You protect your health, away from dust, solvents and glues.

- You save time for your consultations and your personal life!

To find out more about our prices, visit the OPCT® Factory page.